The Humble Brick

Our oldest, engineered building material

I’m new here, and still trying to work out what I want to write about. Readers, I’d love to hear what you would like from me! Musings about my life and career? Posts about how things around us work? The extraordinary (and ordinary) humans behind the engineering? The history of how our humanmade world came to be, one object / material at a time?

This month, let’s try out the last one. Allow me to indulge in some nerdery around one of the oldest building materials: the humble brick.

Find a Lego-related Fun Fact at the end!

If you enjoyed this newsletter, please hit like and share with a friend, it really does help get my work out there.

Materials

When designing a building or bridge, materials are of foremost concern to us engineers. In fact, different materials can entirely change the way the frame of a structure is arranged, how intrusive it feels, and how physically heavy and expensive it is: we need to weave in the skeleton of the structure without it becoming obtrusive. Ultimately, my choice of material has to ensure that the structure survives as long as possible in its environment.

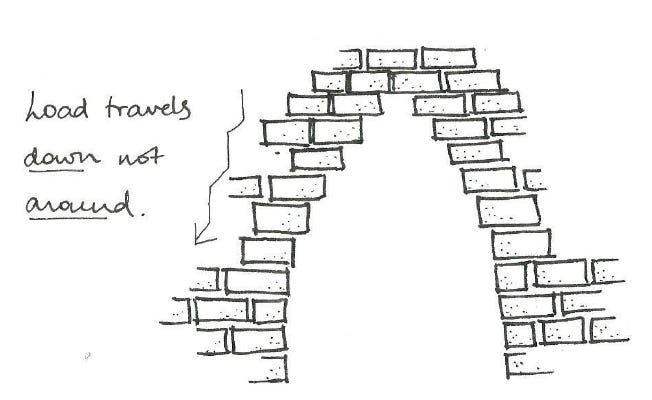

Sketch of a cantilevered arch made from bricks

Bricks

As one of our older, engineered building blocks, bricks were already in use around 9000 BCE. In the deep valley of the River Jordan, hundreds of metres below sea-level, Neolithic human created the city of Jericho. Residents baked hand-moulded flat pieces of clay in the sun and built homes with them in the shape of beehives.

As early as 2900 BCE the Indus Valley Civilisation used bricks baked in kilns. It was a process that required skill and precision: if it wasn’t heated for long enough, the shaped mud wouldn’t dry out properly. Heated too much and too quickly, and it would crack. But if baked at the right temperature for just the right length of time, the mud became strong and weather-resistant.

Today, we ‘fire’ the bricks at even higher temperatures, between 800 and 1,200°C. This makes the particles of the clay fuse together and turns it into a different material: ceramic, which is more similar to glass than dried mud.

These are the strongest types of bricks and can support the weight of five elephants (no elephants were harmed in this thought experiment).

Ingredients

What are bricks made from?

Clay is made up of volcanic rocks that have been ground down to a fine powder. Many (many) years ago, these rocks were picked up by moving water, wind and ice: as they moved, they combined with particles of other minerals, like quartz, mica, lime and iron oxide.

This mixture was deposited far away from its original source in layers at the bottom of rivers, valleys and seas. Plants and animals lived and died in these areas, adding layers of organic or living materials to the ground. Gradually, over millions of years, with changes in temperature and pressure, these layers of crushed rocks, minerals and organic matter turned into clay.

An Ancient Recipe

While writing BUILT, I read through books written by an ancient Roman Masterbuilder, called Vitruvius. This is (broadly) what he said:

Method

1. Throw a lump of clay into knee-deep water and then stir and knead forty times with your feet.

2. Wet the clay with the waters of pine, mango and tree bark, and the water of three fruits, and continue kneading it for a month.

3. Form the clay, mixed with a little water, into large, flat rectangles using a wooden mould.

4. Heat the clay gently and gradually. If made in the summer the bricks will be defective because the heat of the sun will cause their outer layers to harden quickly, while leaving the insides soft and vulnerable. On the other hand, if you make the bricks during the spring or the autumn they will dry out uniformly, due to the milder temperature.

5. After an interval of between two and four months, throw the bricks into water, take them out and allow them to dry completely.

There you have it. The bricks that you might see almost every day have a long history, that have taken us around the world.

Before I go, my Fun Fact!

Around 1.4 trillion bricks are made every year around the world.

China alone manufactures 800 billion, and India makes around 140 billion.

Lego make about 45 billion bricks every year!

I’d love to see more about the underlying structures that shape our world—both the visible and the hidden ones. How do principles of engineering—load-bearing, flexibility, resilience—translate into other fields? Even in something as delicate as lacework (fellow knitter here!) or as monumental as The Shard or The Pantheon in Rome, it's all about balance, tension, and design working in harmony. It would be fascinating to read your perspective on how these principles connect across disciplines and shape both the human-made and natural world. Mental Resilience: bending with life's challenges rather than breaking under them.

Perhaps the real marvel of engineering is the balance between strength and flexibility. Too rigid, and things (people too?) crack under pressure. Too loose, and they lack form... find a way to stand tall while adjusting to the forces around them.

Whatever you write, it's always a pleasure to read!

At a recent exhibition at the Tate Liverpool called Brickworks, they showed this great film called In Comparison by Harun Farocki which showed workers from around the world using different methods to make bricks. It sounds boring but was very engrossing.

https://www.tate.org.uk/visit/tate-liverpool/display/harun-farocki-in-comparison